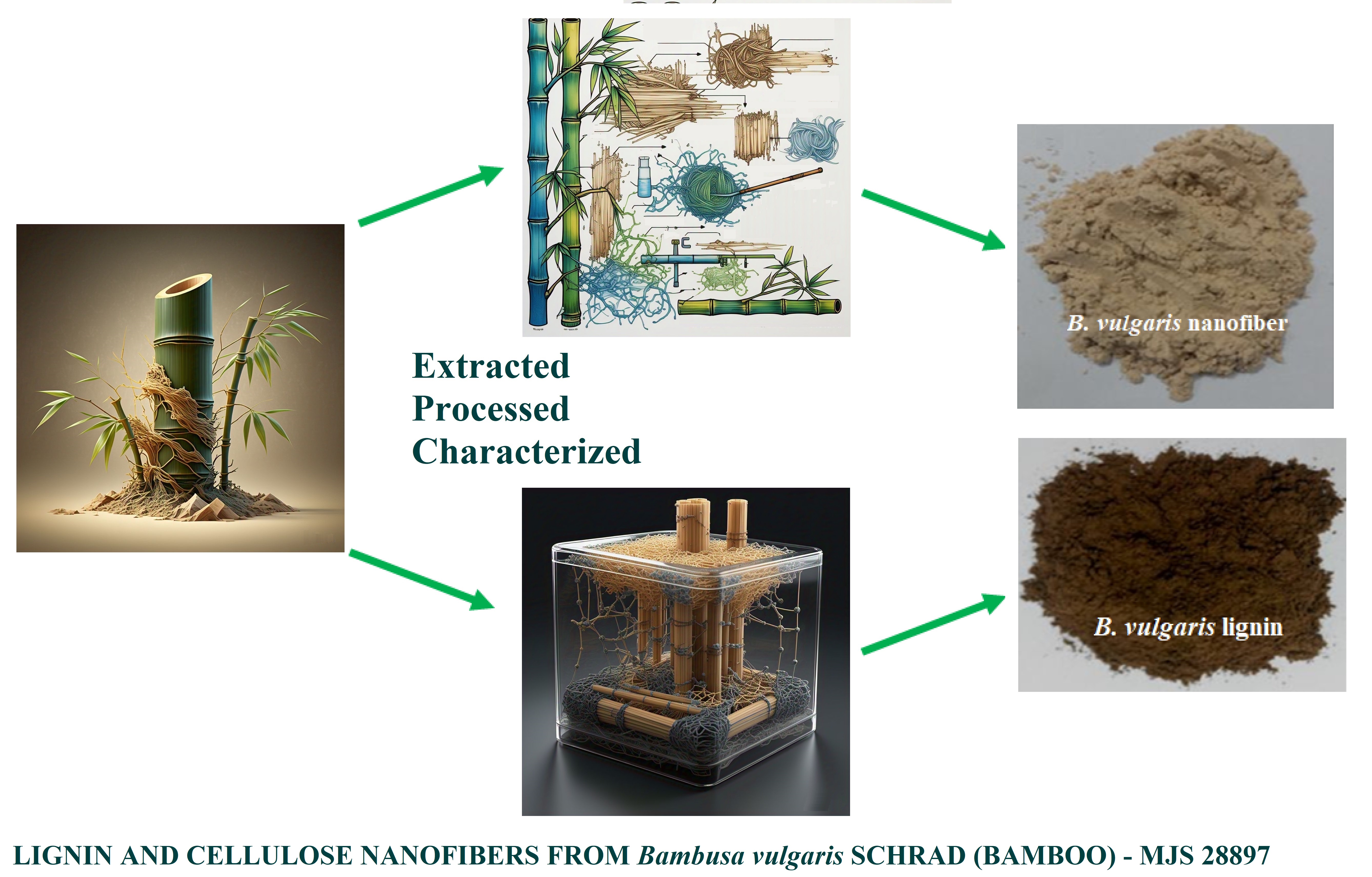

Lignin and Cellulose Nanofibers from Bambusa vulgaris Schrad (Bamboo): An Extraction, Preparation and Characterization Study

DOI:

https://doi.org/10.22452/mjs.vol44no1.1Keywords:

Bamboo, cellulose nanofibers, lignin, materials extraction, materials characterizationAbstract

In this paper, lignin and cellulose nanofibers were extracted and prepared from Bambusa vulgaris schrad (B. vulgaris: bamboo) before being subjected to characterization investigations. These extractions and preparations of the lignin and cellulose nanofibers were carried out chemically using alkali combined with bleaching treatments together with acid hydrolysis and sonication. The cellulose nanofibers were then subjected to morphological and dimensional characterization of the Zetasizer, Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) instruments. The functional groups investigation, using Fourier Transform infrared spectroscopy (FTIR), and thermal degradation via the Thermogravimetric analysis (TGA), of the bamboo lignin and of the cellulose nanofibers were also carried out. Results revealed that the percentage yields of the bamboo lignin and bamboo nanofiber were 21.91 wt% and 33.6 wt% respectively. The SEM and TEM investigations indicated the prepared nanofibers were rod-like in morphology, having sizes ranging from 20 to 100 nm. FTIR showed that the lignin extracted from bamboo typified G-S type lignin while the nanofibers are completely devoid of lignin. TGA revealed that the lignin was more thermally stable than the nanofiber under the test conditions. The obtained lignin and cellulose nanofibers showed promise for possible application as reinforcement agents in biodegradable nanocomposite film preparation.

Downloads

References

Alemdar, A., Sain, M. (2008). Isolation and characterization of nanofibers from agricultural residues, Wheat straw and soy hulls. Bioresource Technology, 99:1664–1671.

Azizi-Samir, M.A.S., Alloin, F., Dufresne, A. (2005). Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules, 6:612–626.

Bao, L., Chen, Y., Zhou, W., Wu, Y., Huang, Y. (2011). Bamboo fibers at poly(ethylene glycol) reinforced poly (butylenes succinate) biocomposites. Journal of Applied Polymer Science, 122:2456–2466.

Beloin C., Roux A., Ghigo J.-M. (2008). “Escherichia coli Biofilms.” In: Romeo, T. (ed.) Bacterial biofilms. Current Topics in Microbiology and Immunology (Volume 322). Springer-Verlag Berlin Heidelberg, 249–289.

Brethauer, S., Shahab, R.L., Studer, M.H. (2020). Impacts of biofilms on the conversion of cellulose. Applied Microbiology and Biotechnology, 104:5201–5212.

Börcsök, Z., Pásztory, Z. (2020). The role of lignin in wood working processes using elevated temperatures: an abbreviated literature survey. European Journal of Wood and Wood Products, doi:10.1007/s00107-020-01637-3.

Chabannes, M., Ruel, K., Yoshinaga, A., Chabbert, B., Jauneau, A., Joseleau, J.P., Boudet, A.M. (2001). In situ analysis of lignins in transgenic tobacco reveals a differential impact of individual transformations on the spatial patterns of lignin deposition at the cellular and subcellular levels. Plant Journal, 28(3):271–282

Chakraborty, A., Sain, M., Kortschot, M. (2006). Reinforcing potential of wood pulp-derived microfibers in a PVA matrix. Holzforschung, 60:53–8.

Coates, J. (2000). “Interpretation of infrared spectra, a practical approach.” In: Meyers, R.A. (Ed.), Encyclopedia of Analytical Chemistry, 10815-10837.

Dinh Vu, N., Thi Tran, H., Bui, N.D., Duc Vu, C., Viet Nguyen, H. (2017). Lignin and cellulose extraction from Vietnam’s rice straw using ultrasound-assisted alkaline treatment method. International Journal of Polymer Science, 2017:1063695.

Elazzouzi-Hafraoui, S., Nishiyama, Y., Putaux, J.L., Heux, L., Dubreuil, F., Rochas, C. (2008). The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules, 9 (1):57–65.

Faix, O. (1991). Classification of lignins from different botanical origins by FT-IR spectroscopy. Holzforschung, 45:21–27.

Ghatak, H.R. (2008). Spectroscopic comparison of lignin separated by electrolysis and acid precipitation of wheat straw soda black liquor. Industrial Crops and Products, 28(2):206–212.

Gibson, L.J. (2012). The hierarchical structure and mechanics of plant materials. Journal of the Royal Society Interface, 9(76):2749–2766.

Gopakumar, D.A., Manna, S., Pasquini, D., Thomas, S. and Grohens, Y. (2018). Nanocellulose: extraction and application as a sustainable material for wastewater purification. In: Hussain, C.M. and Mishra, A.K. (Eds.) New Polymer Nanocomposites for Environmental Remediation, Elsevier Inc., 469–486.

Harman-Ware, A.E., Happs, R.M., Davison, B.H. and Davis, M.F. (2017). The effect of coumaryl alcohol incorporation on the structure and composition of lignin dehydrogenation polymers. Biotechnology for Biofuels, 10(1):1–11.

Ibrahim, M.N., Mohamad, A.H., Yusop M.R.M. (2006). The effects of lignin purification on the performance of iron complex drilling mud thinner. Jurnal Teknologi. 44:83–94.

Jawerth, M.E., Brett, C.J., Terrier, C., Larsson, P.T., Lawoko, M., Roth, S.V., Lundmark, S., Johansson, M. (2020). Mechanical and morphological properties of lignin-based thermosets. ACS Applied Polymer Materials, 2(2):668–676.

John, M.J., Anandjiwala, R.D., Pothan, L.A., Thomas, S. (2007). Cellulosic fiber reinforced green composites. Composite Interface, 14 (7–9):733–751.

Kampeerapappun, P., Aht-ong, D., Pentrakoon, D. and Srikulkit, K., 2007. Preparation of cassava starch/montmorillonite composite film. Carbohydrate Polymers, 67(2):155–163.

Kaushik, A., Singh, M., Verma, G. (2010). Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydrate Polymers, 82:337–345.

Krishnan, V.N., Ramesh, A. (2013). Synthesis and characterization of cellulose nanofibers from coconut coir fibers. IOSR Journal of Applied Chemistry (IOSR-JAC), 6(3):18–23.

Labeeuw, L., Martone, P.T., Boucher, Y., Case, R.J. (2015). Ancient origin of the biosynthesis of lignin precursors. Biology Direct, 10(1):1–21.

Lebo, S.E.J., Gargulak, J.D. and McNally, T.J. (2015). Lignin. Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. doi:10.1002/0471238961.12090714120914.a01.pub3

LeVan, S.L. (1989). Thermal degradation. In: Scniewind A.P. (Ed.), Concise Encyclopedia of Wood and Wood-based Materials. Pergamon Press, New York, 271–273.

Li, J. (2011). Isolation of Lignin from Wood. Saimaa University of Applied Sciences, Imatra Unit of Technology, Degree Programme in Paper Technology. Bachelor’s Thesis, 2011.

Liu, D., Zhong, T., Chang, P.R., Li, K., Wu, Q. (2010). Starch composites reinforced by bamboo cellulosic crystals. Biosource Technology, 101:2529–2536.

Lu, Y., Sun, Q., She, X., Xia, Y., Liu, Y., Li, J., Yang, D. (2013). Fabrication and characterisation of α-chitin nanofibers and highly transparent chitin films by pulsed ultrasonication Carbohydrate Polymer, 98(2):1497–1504.

Martone, P.T., Estevez, J.M., Lu, F., Ruel, K., Denny, M.W., Somerville, C., Ralph, J. (2009). Discovery of lignin in seaweed reveals convergent evolution of cell-wall architecture. Current biology, CB 19(2):169–75.

Menon, M.P., Selvakumar, R., Ramakrishna, S. (2017). Extraction and modification of cellulose nanofibers derived from biomass for environmental application. RSC Advances, 7(68):42750¬–42773.

Ochigbo, S.S., Luyt, A.S., Mofokeng, J.P., Antic, Z., Dramicanin, M.D., Djokovic, V. (2012). Dynamic mechanical and thermal properties of the composites of thermoplastic starch and lanthanum hydroxide nanoparticles. Journal of Applied Polymer Science, doi:10.1002/APP.37859.

Okeniyi, J.O., Akinlabi, E.T., Akinlabi, S.A. and Okeniyi, E.T. (2019). Biochemical characterization data from Fourier transform infra-red spectroscopy analyses of Rhizophora mangle L. bark-extract. Chemical Data Collections, 19:100177.

Okeniyi, J.O., Popoola, A.P.I., Ojewumi, M.E., Okeniyi, E.T. and Ikotun, J.O. (2018). Tectona grandis capped silver-nanoparticle material effects on microbial strains inducing microbiologically influenced corrosion. International Journal of Chemical Engineering, 2018:7161537.

Okeniyi, J.O., John, G.S., Owoeye, T.F., Okeniyi, E.T., Akinlabu, D.K., Taiwo, O.S., Awotoye, O.A., Ige, O.J., Obafemi, Y.D. (2017a). Effects of Dialium guineense based zinc nanoparticle material on the inhibition of microbes inducing microbiologically influenced corrosion. In: Meyers, M.A., Benavides, H.A.C., Brühl, S.P., Colorado, H.A., Dalgaard, E., Elias, C.N., Figueiredo, R.B., Garcia-Rincon, O., Kawasaki, M., Langdon, T.G., Mangalaraja, R.V., Marroquin, M.C.G., da Cunha Rocha, A., Schoenung, J.M., Costa e Silva, A., Wells, M., Yang, W. Proceedings of the 3rd Pan American Materials Congress, Springer, Cham, 21–31.

Okeniyi, J.O., Omotosho, O.A., Inyang, M.A., Okeniyi, E.T., Nwaokorie, I.T., Adidi, E.A., Owoeye, T.F., Nwakudu, K.C., Akinlabu, D.K., Gabriel, O.O., Taiwo, O.S. (2017b). Investigating inhibition of microbes inducing microbiologically-influenced-corrosion by Tectona grandis based Fe-nanoparticle material. In: AIP Conference Proceedings, AIP Publishing LLC, 1814(1):020034.

Okeniyi, J.O. and Popoola, A.P.I. (2017). Understanding eco-friendly anticorrosion prospect on steel-reinforcement in NaCl-immersed concrete from biochemical characterization of Irvingia gabonensis leaf. Contributed Papers from Materials Science and Technology 2017 (MS&T17), 1070–1077.

Okeniyi, J.O., Okeniyi, E.T., Ogunlana, O.O., Owoeye, T.F. and Ogunlana, O.E. (2016). Investigating biochemical constituents of Cymbopogon citratus leaf: Prospects on total corrosion of concrete steel-reinforcement in acidic-sulphate medium. In: TMS 2017 146th Annual Meeting & Exhibition Supplemental Proceedings, Springer, Cham, 341–351.

Paakko, M., Ankerfors, M., Kosonen, H., Nykanen, A., Ahola, S., Osterberg, M., Ruokolainen, J., Laine, J., Larsson, T., Ikkala, O. (2007). Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules, 8(6):1934–1941.

Phanthong, P., Reubroycharoen, P., Hao, X., Xu, G., Abudula, A. and Guan, G. (2018). Nanocellulose: Extraction and application. Carbon Resources Conversion, 1(1):32–43.

Radotić K., Mićić M. (2016). “Methods for extraction and purification of lignin and cellulose from plant tissues.” In: Mićić M. (eds) Sample Preparation Techniques for Soil, Plant, and Animal Samples. Springer Protocols Handbooks. Humana Press, New York, NY. doi:10.1007/978-1-4939-3185-9_26

Rahim, W.R.W.A., Idrus, R.M. (2018). Importance and uses of forest product bamboo and rattan: their value to socioeconomics of local communities. International Journal of Academic Research in Business and Social Sciences, 8(12):1484–1497.

Saito, T., Hirota, M., Tamura, N., Kimura, S., Fukuzumi, H., Heux, L., Isogai, A. (2009). Individualization of nano-sized cellulose fibrils by direct surface carboxylation using tempo catalyst under neutral conditions. Biomacromolecules, 10(7):1992–1996.

Salmén, L., Stevanic, J.S. and Olsson, A.M. (2016). Contribution of lignin to the strength properties in wood fibres studied by dynamic FTIR spectroscopy and dynamic mechanical analysis (DMA). Holzforschung, 70(12):1155–1163.

Saniwan, S., Lalita, V. and Chularat, K. (2012). Starch/cellulose biocomposites prepared by high-shear homogenization/compression molding. Journal of Materials Science and Engineering B, 2(4):213–222.

Shahi, N., Min, B., Sapkota, B., Rangari, V.K. (2020). Eco-friendly cellulose nanofiber extraction from sugarcane bagasse and film fabrication. Sustainability, 12(15):6015.

Shi, Z.J., Xiao, L.P., Xu, F., Sun, R.C. (2012). Physicochemical characterization of lignin fractions sequentially isolated from bamboo (Dendrocalamus brandisii) with hot water and alkaline ethanol solution. Journal of Applied Polymer Science, 125(4):3290¬–3301.

Sumin, K., Lingping, X., Lingyan, M., Xueming, Z., Runcang, S. (2012). Isolation and structural characterization of lignin from cotton stalk treated in an ammonia hydrothermal system. International Journal of Molecular Sciences, 13:15209–15226.

Vazquez, A., Foresti, M.L., Cerrutti, P., Galvagno, M. (2013). Bacterial cellulose from simple and low cost production media by Gluconacetobacter xylinus. Journal of Polymers and the Environment, 21(2):545–554.

Visakh, P.M., Sabu, T. Kristiina O., Aji, P.M. (2012a). Crosslinked natural rubber nanocomposites reinforced with cellulose whiskers isolated from bamboo waste: Processing and mechanical/thermal properties. Composites, Part A, 43:735–741.

Visakh, P.M., Sabu, T., Kristiina, O., Aji, P.M. (2012b). Effect of cellulose nanofibers isolated from bamboo pulp residue on vulcanized natural rubber. Bioresources, 7(2):2156–2168.

Xiao, S., Gao, R., Lu, Y., Li, J., Sun, Q. (2015). Fabrication and characterization of nanofibrillated cellulose and its aerogels from natural pine needles. Carbohydrate Polymers, 119:202–209.

Yong, Z., Xiao-Bin, L., Chang, G., Wei-Jun, L., Ju-Ming, Y. (2012). Preparation and characterization of nano crystalline cellulose from bamboo fibers by controlled cellulase hydrolysis. Journal of Fiber Bioengineering & Informatics, 5(3):263–271.

Zakikhani, P. Zahari,R. Sultan, M.T.H., Majid, D.L. (2014). Bamboo fibre extraction and its reinforced polymer composite material. International Journal of Chemical, Nuclear, Metallurgical and Materials Engineering, 8(4):284–287.

Zhang, J., Elder, T.J., Pu, Y., Ragauskas, A.J., (2007). Facile synthesis of spherical cellulose nanoparticles. Carbohydrate Polymers, 69(3):607–611.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Malaysian Journal of Science

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Transfer of Copyrights

- In the event of publication of the manuscript entitled [INSERT MANUSCRIPT TITLE AND REF NO.] in the Malaysian Journal of Science, I hereby transfer copyrights of the manuscript title, abstract and contents to the Malaysian Journal of Science and the Faculty of Science, University of Malaya (as the publisher) for the full legal term of copyright and any renewals thereof throughout the world in any format, and any media for communication.

Conditions of Publication

- I hereby state that this manuscript to be published is an original work, unpublished in any form prior and I have obtained the necessary permission for the reproduction (or am the owner) of any images, illustrations, tables, charts, figures, maps, photographs and other visual materials of whom the copyrights is owned by a third party.

- This manuscript contains no statements that are contradictory to the relevant local and international laws or that infringes on the rights of others.

- I agree to indemnify the Malaysian Journal of Science and the Faculty of Science, University of Malaya (as the publisher) in the event of any claims that arise in regards to the above conditions and assume full liability on the published manuscript.

Reviewer’s Responsibilities

- Reviewers must treat the manuscripts received for reviewing process as confidential. It must not be shown or discussed with others without the authorization from the editor of MJS.

- Reviewers assigned must not have conflicts of interest with respect to the original work, the authors of the article or the research funding.

- Reviewers should judge or evaluate the manuscripts objective as possible. The feedback from the reviewers should be express clearly with supporting arguments.

- If the assigned reviewer considers themselves not able to complete the review of the manuscript, they must communicate with the editor, so that the manuscript could be sent to another suitable reviewer.

Copyright: Rights of the Author(s)

- Effective 2007, it will become the policy of the Malaysian Journal of Science (published by the Faculty of Science, University of Malaya) to obtain copyrights of all manuscripts published. This is to facilitate:

- Protection against copyright infringement of the manuscript through copyright breaches or piracy.

- Timely handling of reproduction requests from authorized third parties that are addressed directly to the Faculty of Science, University of Malaya.

- As the author, you may publish the fore-mentioned manuscript, whole or any part thereof, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given. You may produce copies of your manuscript, whole or any part thereof, for teaching purposes or to be provided, on individual basis, to fellow researchers.

- You may include the fore-mentioned manuscript, whole or any part thereof, electronically on a secure network at your affiliated institution, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given.

- You may include the fore-mentioned manuscript, whole or any part thereof, on the World Wide Web, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given.

- In the event that your manuscript, whole or any part thereof, has been requested to be reproduced, for any purpose or in any form approved by the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers), you will be informed. It is requested that any changes to your contact details (especially e-mail addresses) are made known.

Copyright: Role and responsibility of the Author(s)

- In the event of the manuscript to be published in the Malaysian Journal of Science contains materials copyrighted to others prior, it is the responsibility of current author(s) to obtain written permission from the copyright owner or owners.

- This written permission should be submitted with the proof-copy of the manuscript to be published in the Malaysian Journal of Science

Licensing Policy

Malaysian Journal of Science is an open-access journal that follows the Creative Commons Attribution-Non-commercial 4.0 International License (CC BY-NC 4.0)

CC BY – NC 4.0: Under this licence, the reusers to distribute, remix, alter, and build upon the content in any media or format for non-commercial purposes only, as long as proper acknowledgement is given to the authors of the original work. Please take the time to read the whole licence agreement (https://creativecommons.org/licenses/by-nc/4.0/legalcode ).